Underground Compressed-Air Energy Storage

Intermittent renewable energy needs large-scale energy storage to become a complete energy solution that is capable of providing reliable power 24/7.

And the media coverage of energy storage has focused on Tesla and its battery systems when many other -arguably more suitable solutions exist.

We have previously covered the following:

Yet we are still missing one of the most promising methods, one that has existed since the 1870s and uses air’s compression and decompression cycles as a scalable and proven rechargeable battery.

Contents

- What is Compressed-Air Energy Storage (CAES)?

- Why is CAES important?

- What are A-CAES and D-CAES?

- What are the benefits of CAES?

- What are the drawbacks of CAES?

- CAES at present

- Alternative CAES

- Conclusion

- External Resources

What is Compressed-Air Energy Storage (CAES)?

Compressed-Air Energy Storage (CAES) refers to a method of storing and releasing energy by compressing and expanding air.

Excess energy can be used to compress air into an airtight container, where it remains pressurised. This is the charging cycle of CAES.

When energy is needed, the compressed air is released, causing it to depressurise and create a powerful wind draft that can power an electrical turbine. This is the discharging cycle of CAES.

A CAES system can range from small cylinders that can fit in a small vehicle like a car or train to the large-scale storage of air within deep salt caverns with volumes exceeding millions of cubic meters.

In this article, we focus on the latter application that is capable of supporting large-scale energy grids.

Why is CAES important?

Intermittent renewables require low-carbon energy storage to replace fossil fuel power plants.

There is currently a large deficit of energy storage to support renewables, and grid operators are struggling to balance the input of renewables directly into the grid, causing large inefficiencies in the network. Intermittent renewables are a significant factor in rising domestic and business electricity prices in the UK.

Meeting this large deficit cannot be done with a single technology. There isn’t an infinite supply of Li-Ion batteries or endless hydroelectric dams, and the deadline for going net zero is 2050.

Therefore, more green energy storage options are urgently needed, and CAES has some unique attributes that make it the optimal option, particularly when an area coincides with the availability of suitable underground salt caverns.

Solutions must be clean, scalable and cost-efficient, and CAES is competitive in all categories.

What are A-CAES and D-CAES?

Without getting too deep into the physics, CAES has nuances when it comes to dealing with the thermodynamics of compressing and expanding a gas. There are two major CAES designs which vary in the handling of heat.

Adiabatic CAES (A-CAES)

In this method, the low-grade heat that is thermodynamically generated during air compression is stored within a thermal sink, such as concrete, rock, water or molten salt.

When the air is released from storage to generate electricity, the stored heat is transferred back to the expanding air to enhance the process. This heat is necessary to produce the necessary drafts to drive the turbines.

A-CAES is the ideal system setup, and only recently was the first commercial A-CAES plant unveiled in Northern China.

Diabatic CAES (D-CAES)

This method is far simpler but comes at the expense of being less efficient and requiring some burning of natural gas. All commercial-scale CAES plants used this technology until recently.

In D-CAES, the heat generated during compression is not stored (or is only partially stored), so heating by burning natural gas is required in the discharge phase to enhance the expansion of air to drive the turbine.

This is much less efficient (40 – 50% round-trip efficiency) and results in some operational emissions.

What are the benefits of CAES?

Historical Use

Similar to pumped-storage hydro, CAES, has been around for a while. The first known patent dates to 1870 and Huntorf, the first large-scale CAES plant, opened in Germany in 1978.

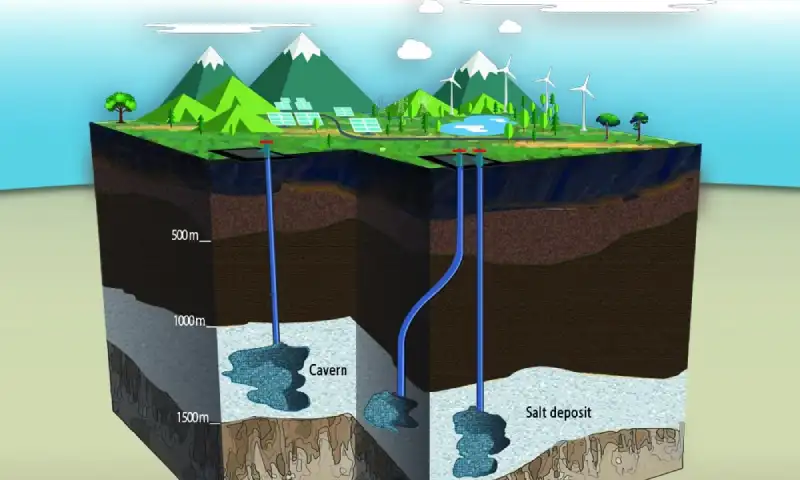

Underground CAES using salt caverns was introduced at Huntorf and is still being used at present. The plant has an energy capacity of approximately 900 MWh when its 600m deep, 310,000m3, and air-tight salt caverns are filled. It takes 8 hours to recharge the caverns and can continuously produce 300MW of electrical power for almost 3 hours to aid in meeting peak electricity demand.

Twenty years later, MacIntosh in Alabama (US) became the second large-scale D-CAES. It uses a 538,000m3 salt cavern at a depth of 450m to store compressed air at approximately 1,100psi, which is approximately 30x the pressure of an average car tyre.

The plant has three generators capable of producing 226MW of power and storing 2,860 MWh of energy, making it the largest electricity storage site in the world if pumped-storage facilities are not counted.

In any case, it proves that CAES is an economic, scalable and long-lasting viable solution, something that novel solutions cannot claim when raising capital.

Scalable

The total amount of energy a CAES system can store is proportional to the volume of the air reservoir and the pressure it can sustain. The larger and stronger the container, the more energy it can hold.

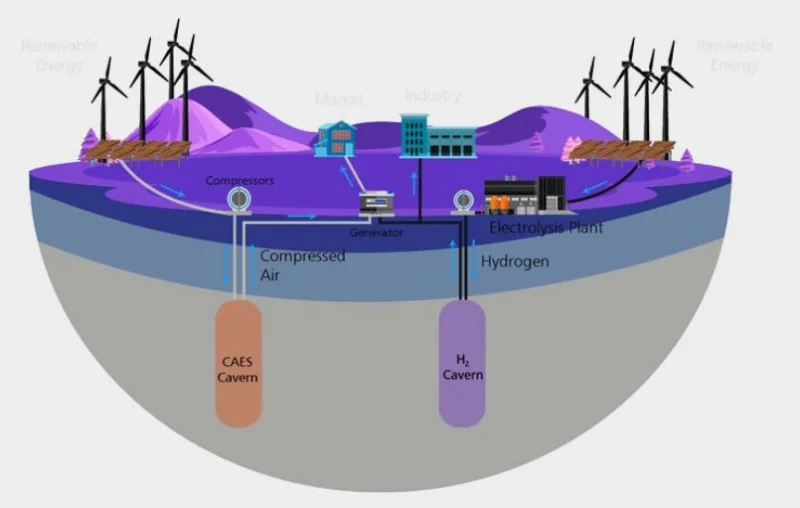

Underground salt caverns are used to store pressurised air in grid-scale CAES because they are structurally and chemically stable: the air doesn’t react with the surrounding salt rock, which can also sustain enormous pressures without leakage.

Typical salt caverns have enormous volumes, ranging between 100,000 m3 and 1,000,000 m3 -enough to hold between 3,000 to 30,000 shipping containers and can hold gas pressures of up to 200 bar (2900 psi).

For this reason, salt caverns have been used for strategic natural gas storage for decades. But as the world decarbonises, there is an expectation that many will become available for scaling CAES, although competition for this space is expected from green hydrogen storage.

On top of quantity, the fact that CAES is a proven technology that is designed to last for many decades also means this scalability is not ephemeral and is proven by Huntorf in Germany, being in operation for 45 years. Contrast this with Li-Ion batteries that cannot last more than a decade.

Adaptable Power Output

One advantage of CAES is that the rate at which energy is produced during discharge can be carefully modulated by adjusting the amount of air being released from the reservoirs.

The responsiveness of these adjustments is typically within a minute, making it suitable for daily re-balancing and frequency stabilisation, both crucial tools for grid operators to keep a stable electricity grid.

Each CAES can be purpose-built depending on its utility. A small turbine translates to a lower power rating but the ability to sustain electricity production of modulation for longer periods of time.

A lifeline for oil & gas companies

Despite their infamous lobbying against climate change, powerful oil & gas companies are fighting a losing battle against the rapid reduction in fossil fuel usage. As a result, they have been actively finding ways of adapting their trillion-dollar infrastructure to participate in green energy instead.

Their principal shift has geared towards carbon capture and hydrogen storage, which can potentially use existing pipes and depleting reservoirs for transport and storage, but CAES could also become part of their portfolio.

Oil & gas companies cannot be allowed to fail because they are so intertwined in the financial system that their collapse may lead to a global financial meltdown, so CAES and its use of salt caverns may be an alternative for the oil and gas companies to adapt.

What are the drawbacks of CAES?

Requires specific geology

Large-scale CAES require very specific underground salt formations that can host the caverns that can store compressed air.

On top of this, many existing caverns are being used as reservoirs for fossil fuel storage, with future competition from underground green hydrogen storage threatening the availability, particularly if hydrogen takes off.

Unlike flywheels or a battery system, installing a CAES system anywhere is impossible.

Not always zero-emissions

Huntorf and MacIntosh D-CAES have associated emissions from using natural gas in their process, which means it is not entirely clean.

In fact, Huntorf uses 1.6kWh of gas to produce 1kWh of electricity, and MacIntosh uses 1.17kWh of gas to produce 1kWh of electricity.

So even if these plants were storing excess wind and solar energy, this storage process is not drastically different from simply having a natural gas plant.

However, A-CAES is another story altogether, with these systems using smart heat exchange and storage methods to avoid the need for natural gas altogether.

The recent unveiling of the A-CAES plant in China essentially defeats the point of this section, but there are no guarantees that some projects may market themselves as CAES when, in fact, they are the cheaper D-CAES alternative in the act of blatant greenwashing.

Not the fastest response time

Live grid re-balancing is becoming increasingly complex as intermittent renewables are connected to the grid, so having energy storage with fast response times is crucial.

Out of all solutions, Flywheels have the fastest response times within the millisecond range, while Li-Ion batteries can start providing energy within a fraction of a second.

In the next broad category lie PSH and CAES, which generally require a fraction of a minute to respond. This is relatively fast and useful for minute-by-minute changes and is not a problem for strategic long-term storage, yet it cannot be used for applications that require granular accuracy.

In other words, it cannot be used as backup power for cloud storage.

Low Efficiency

One of the main weak points of CAES is its lower efficiency compared to virtually all other energy storage sources, except large-scale hydrogen storage, which is still early in its development.

D-CAES such as Huntorf and MacIntosh have efficiencies ranging between 40-50%, which means that over half of the energy stored is lost during a full recharging cycle.

Comparatively, flywheels and concept gravitational storage can have well over 90% efficiencies, while pumped storage hydro and batteries tend to be somewhere between 80-90% efficient.

CAES at present

Only a tiny fraction of large-scale energy storage is currently coming from CAES, with Germany, the US and China being the sole to operate commercial CAES plants.

China is particularly bullish on A-CAES and plans to use this technology to fill 25% of its energy storage capacity.

They are clearly leading the way regarding the A-CAES tech stack, having recently unveiled the first-ever commercial plant in the world.

Zhangjiakou A-CAES can generate 110MW of power without burning any natural gas (unlike its dinosaur predecessors, Huntorf and MacIntosh) and is significantly more efficient at 70% (compared to 40-50% at Huntorf and MacIntosh).

This is a significant leap, with the two large ‘avant-garde’ A-CAES plants under construction in California designed to reach only 60%.

Local Chinese authorities have reported that the peak load energy provided by the Zhangjiakou CAES will save 42,000 tons of coal from being burnt, reducing CO2 emissions by over 100,000 tons annually.

Alternative CAES

Besides A-CAES, there are other advanced alternative ways of storing energy thermodynamically.

Cryogenic Energy Storage (CES)

In CAES, the air is pressurised but always remains in a stable gaseous phase. In Cryogenic Energy Storage (CES), the air is cooled using excess electricity to a temperature below -195 °C using the Claude Cycle to the point where it liquefies into liquid air.

Liquid air takes 0.001% of the volume of gaseous air, which means it can easily fit in overground tanks. When electricity is needed, the liquid air is exposed to ambient air, which causes it to boil back into a gas. This sudden increase in volume can put enough pressure on a large turbine and generate electricity with grid-scale power output.

The process is typically 50% efficient (less efficient than most forms of large-scale energy storage), yet Highview Power’s demo project in the UK is currently yielding 70% efficiency, making this potentially a viable form of energy storage that could be built anywhere (with a preference for locations with low-grade heat such as thermal power stations).

The impressive part is the energy density, which is 1,000 times larger than CAES!

Conclusion

Persevering D-CAES plants like Huntorf and MacIntosh prove that CAES is a reliable technology, while the cutting-edge A-CAES plants in China prove that CAES can be taken to the next efficiency level while eliminating any remaining reliance on fossil fuels.

Unlike Pumped-Storage Hydro, underground CAES is barely noticeable at the surface and may be perfectly suited for oil & gas companies to pivot their existing natural gas storage into green energy storage.

Finally, China’s bet on CAES is a clear indication that the technology is promising and will form part of a large-scale energy storage fuel mix that will include batteries, flywheels, PSH and any other viable alternatives that appear.

The urgency to build green energy storage capacity is making raising capital easier, and we only expect CAES to continue strengthening in the coming years.