Boiler breakdown: Understanding the different types of boilers

This guide explores the different types of boilers, how they work, and why you may need to change your current boiler.

- What are the different types of boilers

- Other less common boilers

- What boiler size do you need

- Should you change your boiler?

- Alternatives to a boiler

What are the different types of boilers

Here’s a breakdown of the most common boilers. We discuss what they are and how each boiler type works.

Combi boilers

A combi boiler is a compact, all-in-one unit that provides heating and hot water without needing a separate hot water cylinder. Combi boilers are designed to be compact and easy to install, making them an ideal choice for small homes and apartments.

How does a combi boiler work?

A combi boiler works in the following way:

- Cold water enters the boiler through a pipe usually connected to the mains water supply.

- The boiler has a heat exchanger that warms the cold water as it passes through. This heat exchanger is powered by a burner fueled by natural gas or propane.

- Once the water is heated, it is delivered directly to the tap or shower head for immediate use. There is no need for a hot water cylinder as hot water is always available on demand.

- A thermostat regulates the temperature of the water as it passes through the heat exchanger, ensuring that the water is heated to the desired temperature.

- Hot water flows through to your taps and showers.

Combi boilers can also provide central heating for your home. The heated water is pumped through radiators or underfloor heating systems to warm up the rooms.

Heat only boilers

These are known as “conventional boilers”. These boilers are separate from the hot water cylinder. They are best suited for homes with a traditional heating system and a hot water cylinder.

How does a heat only boiler work?

It works by heating the water in a storage cylinder or hot water tank and then distributing the hot water throughout the building via a system of pipes and radiators.

The boiler operates by heating the water in the cylinder, which is pumped to the radiators and taps in the building. The radiators give off heat, which warms the rooms, while the hot water in the taps is used for washing, bathing, and other purposes.

A heat only boiler operates using a simple system of three main components: the boiler, the cylinder, and the radiators.

The boiler is commonly found in a cupboard or a basement and is powered by natural gas, oil, or LPG.

It has a heat exchanger that transfers heat from the burning fuel to the water in the cylinder. The cylinder, usually located in an airing cupboard or a loft, stores the hot water produced by the boiler. The radiators in each room distribute the heat throughout the building.

A heat only boiler works by heating water in the cylinder, which is then distributed to the radiators and taps in the building.

The hot water from the cylinder is circulated through the radiators, giving off heat and warming the rooms, while the hot water from the taps is used for washing, bathing, and other purposes.

System boiler

System boilers are similar to combi boilers but require a hot water cylinder to store hot water. They are ideal for larger homes with high hot water demand.

How does a system boiler work?

A system boiler works by:

- Heating water in a storage cylinder is then distributed to radiators and taps throughout the home.

- The system boiler is connected to a sealed central heating system that circulates the water and can be controlled by a thermostat.

- When more hot water is needed in the storage system, the system boiler fires up, and the water is pumped through the system to provide heat.

Unlike a conventional boiler, a system boiler has all the major components built into it (i.e. no tanks in the loft or outside valves needed), making installation simpler and more compact. It also eliminates the need for a separate cold water tank, a common feature of conventional boilers.

Less common boilers

Two other boilers that are less common but important to understand.

Condensing boilers

Condensing boilers are a type of high-efficiency boiler designed to capture and reuse the heat that would otherwise be lost in heating a building or providing hot water.

They use a heat exchanger to extract heat from the flue gases produced when fuel is burned in the boiler.

The heat exchanger in a condensing boiler is designed to cool the flue gases to the point where they condense into water, releasing their latent heat.

This means the boiler can extract more heat from the fuel, resulting in higher efficiency and lower fuel bills.

Condensing boilers are typically more expensive to install than non-condensing boilers. However, their increased efficiency means they can save significant amounts of money on fuel costs over the boiler’s life.

They are also more environmentally friendly, producing fewer greenhouse gas emissions than non-condensing boilers.

Condensing boilers are a popular choice for residential and commercial heating systems due to their high efficiency and cost savings over time.

Biomass boilers

Biomass boilers are a type of renewable energy technology that uses organic materials, such as wood pellets, chips, logs, or agricultural waste, as a fuel source to generate heat.

They work by burning the biomass fuel in a combustion chamber, which produces heat that can be used to provide space heating or hot water for a building or process.

Biomass boilers are often used in off-grid or rural areas without access to natural gas or to reduce reliance on fossil fuels and lower carbon emissions.

They can be installed in residential, commercial, or industrial settings and can be sized to meet the specific heating needs of the building or process.

There are different types of biomass boilers, including stoker boilers, which use a feed system to automatically deliver biomass fuel to the combustion chamber, and fluidised bed boilers, which use a bed of material to burn the biomass fuel to produce heat.

Biomass boilers require regular maintenance and cleaning to ensure optimal performance and efficiency and may require ash removal or storage depending on the biomass fuel used.

They can also be more expensive to install than traditional fossil fuel boilers but can provide cost savings over time due to the lower cost of biomass fuel.

Overall, biomass boilers are a versatile and sustainable alternative to traditional heating systems, offering the potential for significant cost savings and environmental benefits.

What boiler size do you need?

Ideally, you would get an expert to review your property and provide a detailed consultation. They can assess your needs and recommend the right boiler size for your home.

The heating engineer will typically perform a heat load calculation that considers the following:

- Your property’s insulation

- The number and size of windows and;

- Other factors to determine the heat output required.

This calculation will help to determine the appropriate boiler size for your property.

It’s important to note that selecting the correct boiler size is critical to the efficiency and longevity of the boiler.

A boiler that is too small for your property will need to work hard to keep up with the heating demand, leading to increased wear and tear and higher energy bills.

A boiler that is too big for your property will waste energy and be inexpensive to install. Here’s an overview of property size and which boiler size you would need:

| Property Type | No. of Bedrooms | No. of Bathrooms | No. of Radiators | Recommended Boiler Size |

|---|---|---|---|---|

| Apartment/Flat or House with up to 2 bedrooms | 1-2 | 1.0 | Up to 10 | 24kw-27kw |

| Apartment/Flat or House with 2-3 bedrooms and 1 shower | 2-3 | 1.0 | Up to 15 | 28kw-34kw |

| House with 4+ bedrooms and 2 showers | 4+ | 2+ | Up to 28 | 35kw-42kw |

Should I change my boiler?

It entirely depends on your reasoning, but there are a few instances when you should consider changing your boiler:

- Old age: Boilers typically have a lifespan of 10-15 years, and if a boiler is approaching the end of its useful life, it may be more cost-effective to replace it rather than to continue to repair it.

- Boiler efficiency: Older boilers are typically less efficient than newer models, and upgrading to a high-efficiency boiler can significantly reduce costs.

- Home renovations: If homeowners are making significant renovations to their homes, such as adding an extension or upgrading the plumbing system, they may need to replace their boiler to ensure it can handle the increased demand.

- Safety concerns: If a boiler shows signs of wear and tear, such as rust or leaks, it may pose a safety hazard and need to be replaced to ensure the safety of the home’s occupants.

- Environmental concerns: Upgrading to a more eco-friendly boiler can help to reduce a home’s carbon footprint and contribute to a more sustainable future.

Is there an alternative to a boiler?

There are alternatives to the standard boilers; these range from heat pumps to CHP systems; we delve into them a little bit more below:

Heat pumps

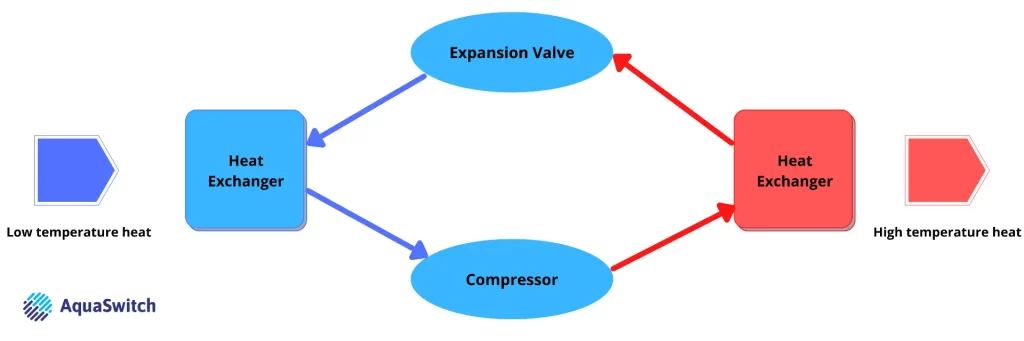

A heat pump is an energy-efficient device that is an alternative to a boiler. Unlike a gas boiler, a heat pump uses electricity and is significantly more efficient than a conventional central heating system. It works by circulating a refrigerant between an outdoor unit (the evaporator) and an indoor unit (the condenser).

During heating, the evaporator absorbs heat from the outside air or ground, and the refrigerant in the evaporator is vapourised.

The refrigerant is then compressed by a compressor inside the heat pump, which raises its temperature and pressure.

The high-pressure, high-temperature refrigerant is then sent to the indoor unit (also known as the condenser), where it releases heat and condenses back into a liquid, which can then be re-circulated to the outdoor unit.

Once complete, the remaining refrigerant expands and cools down. The heat pump is now cold enough to absorb more heat from outside and begin the process again.

Heat pumps can be very efficient because they move heat rather than generate it and can provide more heating or cooling energy than the electrical energy used to operate the system.

They are particularly effective in mild climates and can be a cost-effective alternative to traditional heating and cooling systems.

Combined heat and power (CHP) systems

CHP systems are mainly for larger businesses. A Combined Heat and Power (CHP) system, also known as a cogeneration system, is a technology that generates both electricity and heat from a single fuel source.

In a CHP system, a generator is used to produce electricity, and the heat generated by the generator is captured and used to provide space heating, hot water, or process heat.

The system can be fueled by various sources, including natural gas, biogas, diesel, or biomass. CHP systems are typically more efficient than separate heat and power generation and can help to reduce energy costs and carbon emissions in buildings, factories, and other facilities.

Solar thermal systems

A solar thermal system for a house typically includes solar collectors, a storage tank, and a control system. The solar collectors are usually installed on the roof and absorb sunlight, which heats a fluid circulating through the system.

The heated fluid is then transferred to the storage tank, which provides hot water for showers and taps.

The control system monitors the temperature and flow of the fluid and automatically adjusts the system to ensure maximum efficiency.

Solar thermal systems can help to reduce energy bills and carbon emissions and are a renewable and sustainable alternative to traditional heating systems, i.e. a boiler.

Are you looking to reduce your business energy bill?

You can save on your latest business energy bills by using our business energy comparison service to save on your energy bills.

To compare electricity or gas: