The Rise of Flow Batteries: A New Era

The effort to reach net-zero and phase out fossil fuel power from the British electricity grid is increasing the contribution of intermittent renewables from solar and wind farms.

As the grid becomes more reliant on intermittent renewables, the need for backup power supply to provide electricity on cloudy, windless days becomes increasingly important.

To address this issue, the electricity distribution networks in Britain are rapidly introducing energy storage solutions, including pumped hydro storage, flywheels, and now flow batteries.

Infinity Energy Systems is currently producing a 30 MWh Vanadium Flow Battery, with a capacity equivalent to the daily energy usage of 3,500 homes for the national grid.

This guide explains flow battery technology and its application as an energy storage solution. Here are the key parts of our guide:

- What are flow batteries?

- What are the different types of flow batteries?

- What are the advantages and disadvantages of flow batteries?

- Applications of flow batteries

What are flow batteries?

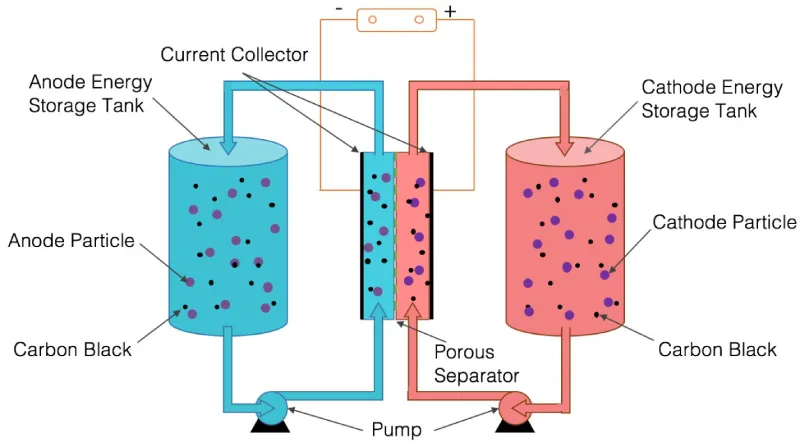

Flow batteries are a type of rechargeable battery that is fundamentally different from traditional rechargeable batteries like Lead-Acid (car batteries), Nickel-metal (AAA batteries), or Lithium-Ion (EV batteries).

Instead of storing the energy within solid electrodes or electrolyte plates, flow batteries store energy in liquid electrolytes contained in external tanks. During recharge-discharge cycles, the stored electrolytes are allowed to circulate through electrochemical cells, where energy conversion occurs.

This design enables flexible scaling of power and energy capacity, making them suitable for medium to large-scale energy storage. Their modularity and ability to provide long-duration discharge make them an attractive option for homes, businesses, industry, grid support and intermittent renewable projects.

What is the capacity and power of flow batteries?

Flow batteries are, by design, highly customisable.

- Capacity, measured in kilowatt-hours (kWh), is determined by the volume and concentration of the electrolytes in the external tanks.

- Power, rated in kilowatts (kW), depends on the size and design of the electrochemical cells.

This unique feature allows flow batteries to be tailored for a variety of applications that require multi-hour charge-discharge cycles, including:

- Home energy storage (5 – 10kW; 20 to 40 kWh) – Their modularity, long lifespan, and in many cases, non-toxicity could make some flow batteries fill in this niche in combination with solar panels.

- Grid energy storage – Attaching Flow batteries to the grid may help with load rebalancing/peak shaving, storing excess energy at off-peak times and releasing it during peak demand. Arrays of high-capacity flow batteries could be used for MW power outputs and MWh capacities.

- Shifting intermittent renewables – Flow batteries to support intermittent renewables on-site could turn intermittent renewables like wind and solar power into uninterruptable baseload power sources.

- Power conversion – In fact, by cyclically varying the number of cells in use during a discharge, Flow Batteries may also be used as AC/DC transformers or even voltage optimisers. This is already covered by existing infrastructure, but Flow Batteries could potentially fill in two roles simultaneously at a range of storage capacities and power outputs.

What are the different types of flow batteries?

Here’s where things start getting intricate, as there are so many combinations and possibilities that flow. Batteries seem like a whole new universe in themselves.

There are three types of flow batteries:

Redox Flow Batteries (RFBs): This is the “traditional” design in which inorganic electrolyte chemistries are used, like Vanadium Redox Flow Batteries (VRFB). As you can see in the subsequent sections, these are the most developed type and the most widely installed.

Organic Flow Batteries: These are a group of “cutting-edge” designs that use organic molecules, often in combination with inorganic elements, as electrolytes. Organic flow batteries may be lower cost, more sustainable, and potentially tailor-made, as the electrochemical properties of the molecules can be modified in the lab.

Hybrid Flow Batteries: This third type of flow battery is not a hybrid between “organic” and “redox” designs but a combination of solid components from traditional and liquid components of flow batteries. An example is the rapidly growing family of Zinc-Bromine batteries that have been used for nearly a decade, using Zinc electrodes to store charge at higher densities than VRFB.

What are the advantages and disadvantages of flow batteries?

Although there are several different types of flow batteries, here is a summary of their key advantages and disadvantages compared with other forms of energy storage:

Advantages of flow batteries

Here are the six key advantages of flow battery technology.

- Scalability: Allow for independent scaling of power and energy capacity, providing flexibility in design and application.

- Long life cycle: Can endure tens of thousands of charge and discharge cycles with minimal degradation, making them suitable for long-term energy storage solutions. This also reduces the need for waste disposal and recycling.

- Flexible discharge: This can provide continuous discharge over short or extended periods, depending on the application. But most importantly, it makes them suitable for daily grid re-balancing or peak shaving, as well as renewable energy integration.

- Low maintenance: This is generally an advantage of all battery systems, but flow batteries often require little maintenance, contributing to lower operational costs.

- Environmental considerations: Non-toxic flow battery chemistries (like organic electrolytes) and those that do not rely on scarce metals can be significantly greener than Lithium-Ion or Lead Acid batteries.

- Thermal stability: Flow batteries tend to have good thermal stabilities, reducing the risk of thermal runaway (fire!).

Disadvantages of flow batteries

Here are the six key drawbacks of current flow battery technology.

- Complexity: The complex design of flow batteries involves higher initial costs than lithium-ion technology.

- Energy density: Flow batteries typically have lower energy densities than lithium-ion, making them bulkier and less suitable for applications where space or weight is a constraint, like in EVs.

- Material costs: Flow batteries that rely on metals like vanadium may face challenges related to material availability and cost due to inflexible supply chains.

- Efficiency: While generally efficient, flow batteries may have lower round-trip efficiency compared to some other battery types, particularly at partial states of charge.

- Relatively immature: Compared to Li-ion and Lead-Acid batteries, commercial flow batteries are much newer, and some types and configurations may have limited commercial availability or support. The exception is Vanadium Redox Flow Batteries.

- Freezing risk: In very cold environments, there may be a risk of electrolyte freezing, requiring additional measures to maintain temperature.

Applications of flow batteries

The first commercial flow battery installation was a 300kW Zinc-Chlorine Redox flow battery installed in Indiana, US, in the early 1980s to provide backup power for a telecoms facility.

Nowadays, hundreds, if not thousands, of flow batteries are installed to support remote installations, renewable energy projects, microgrids, or even large-scale energy grids. The table below lists some notable flow battery installations:

| Name/Project | Location (Installation Date) | Capacity (Power/Energy) | Type | Use Case |

|---|---|---|---|---|

| Dalian Rongke Power Station | Dalian, China (2022) | 100 MW / 400 MWh | Vanadium Redox (VRFB) | Grid-Scale Energy Storage - Currently the largest VRFB in the world |

| Hokkaido Electric Power | Hokkaido, Japan (2015) | 15 MW / 60 MWh | Vanadium Redox (VRFB) | Renewable Energy Integration - It was the largest VRFB in the world for many years |

| UniEnergy Technologies | Washington, USA | 2 MW / 8 MWh | Vanadium Redox (VRFB) | Microgrid Support - The largest containerised flow battery (20 containers). |

| Gills Onions Facility | California, USA | 600 kW / 2.8 MWh | Vanadium Redox (VRFB) | Industrial Energy Management - Installed in an onion processing plant! |

| Anaergia Waste-to-Energy Project | California, USA | 500 kW / 2 MWh | Zinc-Bromine Flow Battery (Hybrid) | Microgrid Support - 192 energy-dense power units stored in cabinets. |

You may notice that besides Reflow’s Zinc-Bromine battery, the vast majority in this sample are Vanadium Redox Flow Batteries (VRFB). This is the most commonly installed type of flow battery for multiple reasons.

This section succinctly covers the real-world applications of flow batteries, highlighting their growing presence in various energy systems.

Why is VRFB more common than other types of flow batteries?

The Vanadium Redox Flow Battery (VRFB) succeeded above other types because of a number of reasons:

Stability & lifespan: VRFBs have superior stability and lifespan because they use the same vanadium electrolyte in both tanks (only the oxidation state varies), as opposed to other batteries that use different chemicals in each, making them prone to cross-contamination.

Material availability: Vanadium is relatively abundant and can be sourced from various minerals and industrial byproducts. This availability has facilitated the commercial development of VRFBs.

Scalability and flexibility: The design of VRFBs allows for independent scaling of energy capacity and power output, providing flexibility for various applications, from grid-scale energy storage to industrial use.

Low toxicity: The aqueous solution used in VRFBs is considered less toxic than other materials used in other flow batteries.

Established technology: Having been extensively researched, developed, iterated and proven in real-life, VRFBs are now considered a mature, successful technology. Other kinds of flow batteries don’t have this, so I have not seen the same level of commercial support.

While other flow battery technologies may offer specific advantages in certain applications or contexts, combining these factors has contributed to VRFBs becoming the poster boy and gold standard of flow batteries.

Their balance of performance, cost, flexibility, and commercial maturity has made them an attractive option in the growing energy storage market.

The future of flow batteries

Ultimately, energy storage is lacking at all scales and niches. If flow batteries can remain competitive in terms of price and performance, there’s no reason why they won’t become a multi-billion-dollar market within a decade or two.

The exponential growth of intermittent renewable capacity is crying out for large-scale storage, while our increasing reliance on the digital world requires clean sources of uninterruptable power supply that only responsive energy storage can provide.

The phasing out of fossil fuel plants, which used to provide grid stability services like load rebalancing and peak shaving through their spinning reserve, also needs urgent replacement and flow batteries are poised for these applications.

Then there are alternative niches that flow batteries can fill, especially in static applications like home and business energy storage, micro and distributed grids, off-grid energy storage, and industrial energy management, to name a few.

Remember, the main advantage of flow batteries is their ‘modular scalability’. Similarly to nuclear SMRs, if you want more capacity, you simply increase the size or number of tanks, and if you want more power, you simply increase the size of the electrochemical cell!

On the other hand, supply chain issues, geopolitical factors, and regional energy policies may ultimately influence their fate.

Flow batteries FAQs

Here are our answers to frequently asked questions regarding flow batteries:

How long do redox flow batteries last?

Redox flow batteries are known for their long cycle life, often lasting over 10,000 charge-discharge cycles. Depending on the specific design, chemistry, and usage, a redox flow battery can last 15 to 20 years or more.

Their longevity is partly due to the separation of energy storage and power generation, allowing for independent scaling and reducing wear on the system, especially with regular maintenance and proper operation.

This long lifespan makes redox flow batteries an attractive option for applications requiring durable and consistent energy storage, such as grid support and renewable energy integration.

How much does vanadium redox flow battery (VRFB) cost per kWh?

According to this MIT paper, the levelised cost of storage of VRFBs is somewhere between $200 and $600 per kWh of electricity.

Factors influencing the cost include the purity and availability of vanadium, the complexity of the system, economies of scale, and technological advancements. Ongoing research is likely to lead to further cost reductions in the future.

Other flow battery technologies like Zinc-Bromine have seen massive cost reductions and are rapidly being rolled out around the world by companies like RedFlow.

Who is making flow batteries?

The list below is non-exhaustive and represents a selection of established companies and innovative startups that are leading the way in the production of commercial flow batteries:

- Sumitomo Electric Industries: A major player in the Vanadium Redox Flow Battery (VRFB) market, particularly in Japan.

- Rongke Power: Another leading manufacturer of VRFBs, known for their installation in Dalian Rongke Power Station in China.

- UniEnergy Technologies: A U.S.-based company building VRFBs for grid and microgrid applications.

- RedFlow: An Australian company that produces Zinc-Bromine flow batteries, focusing on residential and commercial energy storage.

- CellCube: A Canadian company that offers VRFB solutions for renewable energy integration and grid support.

- VoltStorage: A German company developing Redox Flow Batteries for residential energy storage.

- ESS Inc: A U.S.-based company that produces Iron Flow Batteries for commercial, industrial, and utility-scale applications.

- Schmid Group: A German company that has developed VRFBs for various energy storage applications.

- Vanadis Power GmbH: A German company specializing in VRFBs for grid-scale energy storage.

- Primus Power: A U.S.-based company that has developed Zinc-Bromine flow batteries for industrial and grid applications.

Why are AAA batteries NOT flow batteries?

AAA (Triple-A) batteries are not flow batteries because of their fundamental differences in design and operation. They are a type of dry cell battery where the energy is stored within solid electrodes and a fixed electrolyte. The chemical reactions that produce electricity occur within a contained and sealed environment, making them great for small mobile devices.

On the other hand, flow batteries store energy in liquid electrolytes that are housed in external tanks and pumped through electrochemical cells during recharging and discharging cycles. This design is heavy and takes up space, making it more suitable for large-scale energy storage.

Essentially, one is not better than the other; they’re just different!

Why are Lead Acid batteries (car batteries) not Flow batteries?

They may be housed inside containers, but Lead Acid batteries are fundamentally different from Flow batteries. Lead Acid batteries use solid electrodes and a fixed electrolyte, while Flow batteries store energy in liquid electrolytes in external tanks, circulating them through cells.

This makes each of them suitable for distinct applications, with Lead Acid batteries being perfect for rechargeable mobile applications like road vehicles, while Flow batteries’ inherent power and capacity scalability make them more suitable for grid-scale storage.